Dihedral (Shanghai) Science and Technology Co., Ltd

Dihedral (Shanghai) Science and Technology Co., Ltd

- Home

-

Products

-

- Semiconductor crystal

-

Single crystal substrate

-

Multifunctional single crystal substrate

- Barium titanate (BaTiO3)

- Strontium titanate (SrTiO3)

- Iron doped strontium titanate (Fe:SrTiO3)

- Neodymium doped strontium titanate (Nd:SrTiO3)

- Aluminium oxide (Al2O3)

- Potassium tantalum oxide (KTaO3)

- Lead magnesium niobate–lead titanate (PMN-PT)

- Magnesium oxide (MgO)

- Magnesium aluminate spinel (MgAl2O4)

- Lithium aluminate (LiAlO2)

- Lanthanu m aluminate (LaAlO3)

- Lanthanu m strontium aluminate (LaSrAlO4)

- (La,Sr)(Al,Ta)O3

- Neodymium gallate (NdGaO3)

- Terbium gallium garnet (TGG)

- Gadolinium gallium garnet (GGG)

- Sodium chloride (NaCl)

- Potassium bromide (KBr)

- Potassium chloride (KCl)

-

Multifunctional single crystal substrate

-

Functional crystal

- Optical window

- Scintillation crystal

-

Laser crystal

- Rare earth doped lithium yttrium fluoride (RE:LiYF4)

- Rare earth doped lithium lutetium fluoride (RE:LiLuF4)

- Ytterbium doped yttrium aluminium garnet (Yb:YAG)

- Neodymium doped yttrium aluminium garnet (Nd:YAG)

- Erbium doped yttrium aluminium garnet (Er:YAG)

- Holmium doped yttrium aluminium garnet (Ho:YAG)

- Nd,Yb,Er,Tm,Ho,Cr,Lu Infrared laser crystal

- N* crystal

- Metal single crystal

- Material testing analysis

- Material processing

- Scientific research equipment

-

-

Epitaxial Wafer/Films

-

Inorganic epitaxial wafer/film

- Gallium Oxide epitaxial wafer (Ga2O3)

- ε - Gallium Oxide (Ga2O3)

- Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

- Lithium niobate thin film epitaxial wafer

- Lithium tantalate thin film epitaxial wafer

- InGaAs epitaxial wafer

- Gallium Nitride(GaN) epitaxial wafer

- Epitaxial silicon wafer

- Yttrium Iron Garnet(YIG) epitaxial wafers

- Fullerenes&Fullerols

- ε-Gallium Oxide(Ga2O3)

- Indium Arsenide (InAs) epitaxial wafer

- InGaAs and other compound epitaxial wafers

- Periodic polarization of lithium niobate PPLN and lithium tantalate PPLT

-

Inorganic epitaxial wafer/film

- Functional Glass

- Fine Ceramics

-

2-D material

- 2-D crystal

-

Layered transition metal compound

- Iron chloride (FeCl2)

- Niobium sulfide (NbS3)

- Gallium telluride iodide (GaTeI)

- Indium selenide (InSe)

- Copper indium phosphide sulfide (CuInP2S6)

- Tungsten sulfide selenide (WSSe)

- Iron germanium telluride (Fe3GeTe2)

- Nickel iodide (NiI2)

- Iron phosphorus sulfide (FePS3)

- Manganese phosphorus selenide (MnPSe3)

- Manganese phosphorus sulfide (MnPS3)

- Interface thermal conductive materials

-

Epitaxial Wafer/Films

-

-

High-purity element

- Non-metallic

-

Metal

- Scandium (Sc)

- Titanium (Ti)

- Indium (In)

- Gallium (Ga)

- Bismuth (Bi)

- Tin (Sn)

- Zinc (Zn)

- Cadmium (Cd)

- Antimony (Sb)

- Copper (Cu)

- Nickel (Ni)

- Molybdenum (Mo)

- Aluminium (Al)

- Rhenium (Re)

- Hafnium (Hf)

- Vanadium (V)

- Chromium (Cr)

- Iron (Fe)

- Cobalt (Co)

- Zirconium (Zr)

- Niobium (Nb)

- Tungsten (W)

- Germanium (Ge)

- Iron(Fe)

-

Compound raw materials

-

Oxide

- Tungsten Trioxide (WO3)

- Hafnium Dioxide (HfO2)

- Ytterbium Oxide (Yb2O3)

- Erbium Oxide (Er2O3)

- Lanthanu m Oxide (La2O3)

- Cerium Dioxide (CeO2)

- Tin Dioxide (SnO2)

- Niobium Oxide (Nb2O3)

- Zirconium Dioxide (ZrO2)

- Zinc Oxide (ZnO)

- Copper Oxide (CuO)

- Magnetite (Fe3O4)

- Titanium Dioxide (TiO2)

- Samarium (III) oxide (Sm2O3)

- Silicon Dioxide (SiO2)

- Aluminum Oxide (Al2O3)

- Gallium Oxide Ga2O3(Powder)

- Sulfide

- Fluoride

- Nitride

- Carbide

-

Halide

- Gallium Chloride (GaCl3)

- Indium Chloride (InCl3)

- Aluminum Chloride (AlCl3)

- Bismuth Chloride (BiCl3)

- Cadmium Chloride (CdCl2)

- Chromium Chloride (CrCl2)

- Chromium Chloride Hydrate (CrCl2(H2O)n)

- Copper Chloride (CuCl)

- Copper Chloride II (CuCl2)

- Cesium Chloride (CsCl)

- Europium Chloride (EuCl3)

- Europium Chloride Hydrate (EuCl3.xH2O)

- Magnesium Chloride (MgCl2)

- Sodium Chloride (NaCl)

- Nickel Chloride (NiCl2)

- Indium Chloride (InCl3)

- Indium Nitrate Hydrate (In(NO3).xH2O)

- Rubidium Chloride (RbCl3)

- Antimony Chloride (SbCl3)

- Samarium Chloride (SmCl3)

- Samarium Chloride Hydrate (SmCl3.xH2O)

- Scandium Chloride (ScCl3)

- Tellurium Chloride (TeCl3)

- Tantalum Chloride (TaCl5)

- Tungsten Chloride (WCl6)

- Aluminum Bromide (AlBr3)

- Barium Bromide (BaBr2)

- Cobalt Bromide (CoBr2)

- Cadmium Bromide (CdBr2)

- Gallium Bromide (GaBr3)

- Gallium Bromide Hydrate (GaBr3.xH2O)

- Nickel Bromide (NiBr2)

- Potassium Bromide (KBr)

- Lead Bromide (PbBr2)

- Zirconium Bromide (ZrBr2)

- Bismuth Bromide (BiBr4)

- Bismuth Iodide (BiI3)

- Calcium Iodide (CaI2)

- Gadolinium Iodide (GdI2)

- Cobalt Iodide (CoI2)

- Cesium Iodide (CsI)

- Europium Iodide (EuI2)

- Lithium Iodide (LiI)

- Lithium Iodide Hydrate (LiI.xH2O)

- Gallium Iodide (GaI3)

- Gadolinium Iodide (GdI3)

- Indium Iodide (InI3)

- Potassium Iodide (KI)

- Lanthanu m Iodide (LaI3)

- Lutetium Iodide (LuI3)

- Magnesium Iodide (MgI2)

- Sodium Iodide (NaI)

-

Oxide

-

High-purity element

-

-

Sputtering Target

-

Metal target material

- Gold (Au(T))

- Silver (Ag(T))

- Platinum (Pt(T))

- Palladium (Pd(T))

- Ruthenium (Ru(T))

- Iridium (Ir(T))

- Aluminium (Al(T))

- Copper (Cu(T))

- Titanium (Ti(T))

- Nickel (Ni(T))

- Chromium (Cr(T))

- Cobalt (Co(T))

- Iron (Fe(T))

- Manganese (Mn(T))

- Zinc (Zn(T))

- Vanadium (V(T))

- Tungsten (W(T))

- Hafnium (Hf(T))

- Niobium (Nb(T))

- Molybdenum (Mo(T))

- Lanthanu m (La (T))

- Cerium (Ce (T))

- Praseodymium (Pr (T))

- Neodymium (Nd (T))

- Samarium (Sm (T))

- Europium (Eu (T))

- Gadolinium (Gd (T))

- Terbium (Tb (T))

- Dysprosium (Dy (T))

- Holmium (Ho (T))

- Erbium (Er (T))

- Thulium (Tm (T))

- Ytterbium (Yb (T))

- Lutetium (Lu (T))

- Alloy target material

- Semiconductor target material

-

Oxide target material

- Aluminum Oxide (Al2O3(T))

- Silicon Dioxide (SiO2(T))

- Titanium Dioxide (TiO2(T))

- Chromium Oxide (Cr2O3(T))

- Nickel Oxide (NiO(T))

- Copper Oxide (CuO(T))

- Zinc Oxide (ZnO(T))

- Zirconium Oxide (ZrO2(T))

- Indium Tin Oxide (ITO(T))

- Indium Zinc Oxide (IZO(T))

- Aluminum Doped Zinc Oxide (AZO(T))

- Cerium Oxide (CeO2(T))

- Tungsten Trioxide (WO3(T))

- Hafnium Oxide (HfO2(T))

- Indium Gallium Zinc Oxide (IGZO(T))

- Nitride target material

- Sulfide target material

-

Antimony tellurium selenium boron target material

- Magnesium Boride (MgB2(T))

- Lanthanu m Hexaboride (LaB6(T))

- Titanium Diboride (TiB2(T))

- Zinc Selenide (ZnSe(T))

- Zinc Antimonide (Zn4Sb3(T))

- Cadmium Selenide (CdSe(T))

- Indium Telluride (In2Te3(T))

- Tin Selenide (SnSe(T))

- Germanium Antimonide (GeSb(T))

- Antimony Selenide (Sb2Se3(T))

- Antimony Telluride (Sb2Te3(T))

- Bismuth Telluride (Bi2Te3(T))

-

Metal target material

-

Sputtering Target

-

- Services

- Media

- Partner

- Contact Us

- About

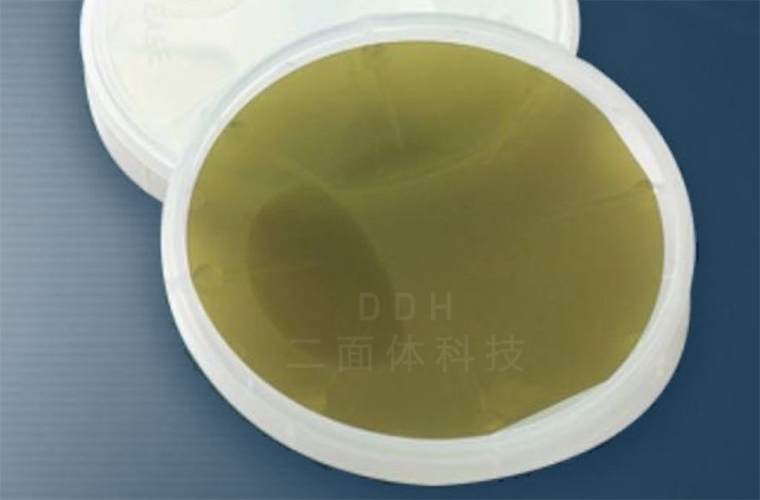

碳化硅 SiC

碳化硅(SiC)是一种独特的半导体材料,具有一些优异的物理特性,它以其单晶结构,独特的性能优势,广泛的应用以及广阔的发展前景受到广泛的关注。

在结构上,碳化硅单晶主要有多种晶体多形性,包括3C-SiC、4H-SiC、6H-SiC等,这些不同的晶体结构都有各自独特的性能。其中,4H-SiC和6H-SiC以其优秀的电子性能和较高的热导率被广泛应用。

碳化硅的性能优势主要包括宽的禁带宽度、高的电子迁移率、强的热稳定性、良好的化学稳定性和优秀的热导性。其中,宽禁带使得SiC具有高的电子穿透能力,有利于在高温、高压、高频等恶劣环境下运行。高电子迁移率和热导性使得SiC有着很好的开关性能和散热性能。

碳化硅的应用领域非常广泛,包括电力电子、光电子、高温电子、汽车电子等。例如,SiC可以作为功率器件的基础材料,用于电力转换和调控,大大提高了能效。在光电子领域,SiC因其能够承受极端环境的能力而被用于制作太阳能电池。此外,SiC也被广泛应用于电动汽车和混合动力汽车的功率转换系统,带来了显著的能效提升。

碳化硅的发展前景非常广阔。随着技术的不断发展,SiC的生产成本正在逐步降低,使其更广泛地应用于各种领域。而在新能源汽车、风电、太阳能发电等新兴领域,碳化硅的应用也会得到更广泛的开展。同时,随着电力电子设备对效能的更高要求,SiC的优异性能使其在这些领域的应用有着巨大的潜力。总的来说,碳化硅作为一种优秀的半导体材料,将在未来有着更广泛和深入的应用。

二面体科技提供多种规格订制的高质量SiC晶体材料

Applications

• 电力电子设备:由于SiC的高温、高电压特性,它在电力电子设备中被广泛应用,如电力变换器、高频开关电源、充电设备等。

• 汽车电子设备:SiC在电动汽车的功率电子转换器、车载充电器等设备中有广泛的应用,可以提高能效并降低体积。

• 光伏设备:SiC材料在光伏设备中被用作逆变器,可以提高系统的转换效率和稳定性。

• 射频设备:由于SiC的高频特性,它在射频功率放大器和微波设备中有广泛应用。

• LED灯:SiC单晶可作为蓝色LED灯的衬底材料,以提高LED灯的效率和寿命。

• 热电装置:SiC的高热导率和电绝缘性能使得其在热电设备中有很大的应用潜力。

• 耐磨材料:由于SiC的高硬度,它经常被用作耐磨材料,如砂纸、磨具等。

Features

• 高温稳定性:碳化硅具有非常高的熔点(约2730℃),在高温环境下保持稳定性,适合用于高温应用。

• 高硬度:碳化硅是世界上已知硬度仅次于金刚石和立方氮化硼的硬质材料,因此在磨削和切割等工具上有重要应用。

• 耐磨性:除了高硬度,碳化硅也具有良好的耐磨性,使得它在各种需要耐磨的应用中都有广泛用途。

• 出色的热导性:碳化硅的热导率很高,这使得它在需要快速散热的电子设备和其他设备中都有优势。

• 耐化学侵蚀:碳化硅对大多数化学试剂都有较好的抗腐蚀性,使其在各种恶劣环境中仍能保持性能。

• 优良的半导体特性:碳化硅的能隙宽度较大,适合用于高电压和高温环境下的功率电子设备。

• 低热膨胀系数:碳化硅的热膨胀系数相对较低,使得它在温度变化时,尺寸变化不大,有利于保持设备的稳定性。

• 高强度:碳化硅是一种高强度材料,可在各种高压环境中工作,非常适合用于高压设备和组件。

-

生长方法

籽晶升华法 ,PVT(物理气相传输)

晶体结构

六方

晶格常数

a=3.08 Å c=15.08 Å

排列次序

ABCACB

方向

生长轴或 偏<0001>3.5 º

带隙

2.93 eV (间接)

硬度

9.2(mohs)

热传导@300K

5 W/ cm.k

介电常数

e(11)=e(22)=9.66 e(33)=10.33

尺寸

10x3,10x5,10x10,15x15,,20x15,20x20,

dia2”, 15 x 15 mm,10x10mm等

厚度

0.5mm,1.0mm

抛光

单面或双面

晶向

<001>±0.5º

晶面定向精度:

±0.5°

边缘定向精度:

2°(特殊要求可达1°以内)

斜切晶片

可按特定需求,加工边缘取向的晶面按特定角度倾斜(倾斜角1°-45°)的晶片

Ra:

≤5Å(5µm×5µm)

包装

100级洁净袋,1000级超净室